New Step by Step Map For cvt

New Step by Step Map For cvt

Blog Article

A standard automatic gearbox works by using gears to match engine pace to road pace. At minimal pace, the motor turns a small gear which is linked to a bigger gear that turns the wheels by way of other transmission components.

Escalating the gap enables the belt to experience further during the “groove”, Therefore properly lowering the pulley size. Decreasing the gap has the other influence; the belt rides bigger, as if in a larger pulley.

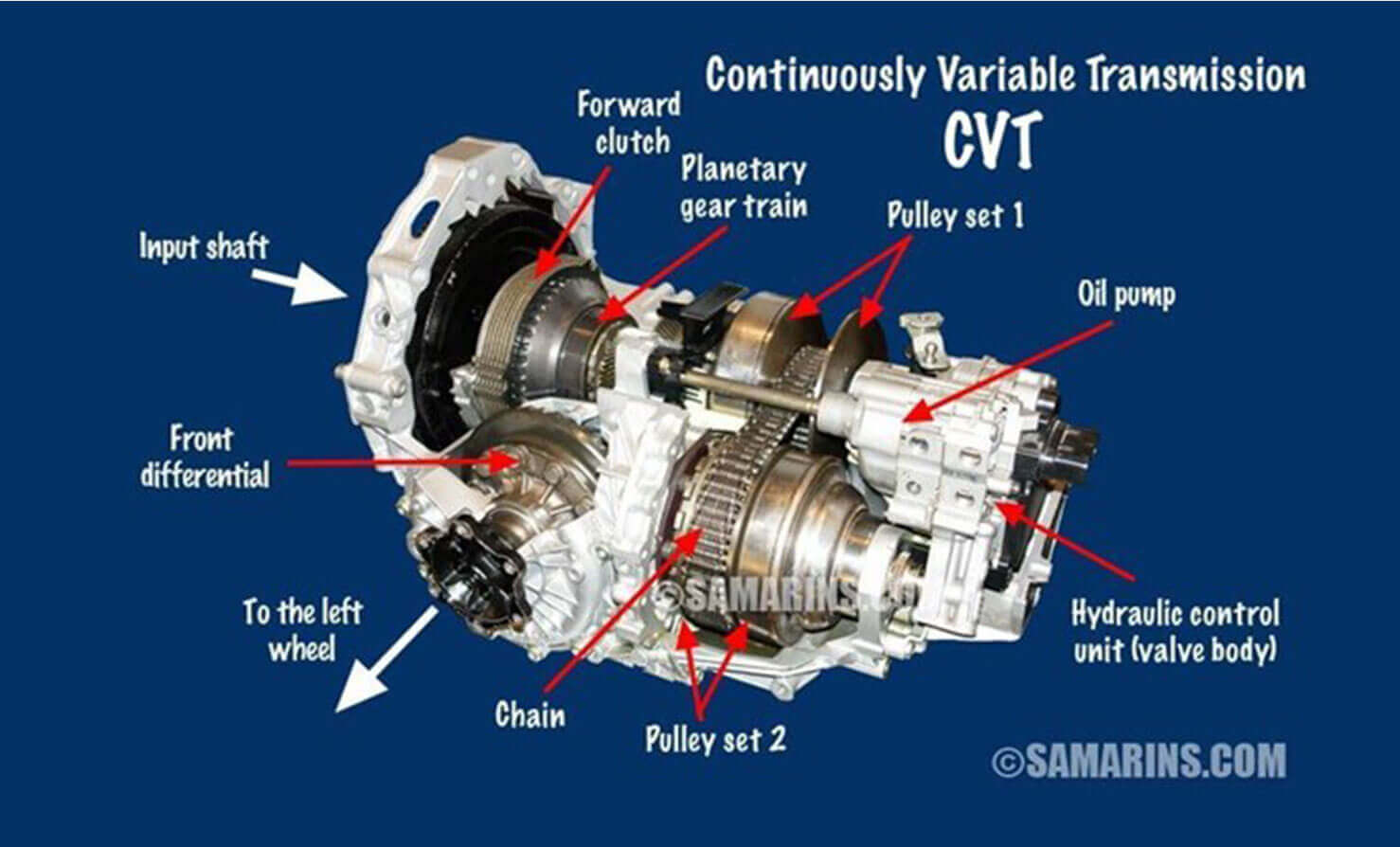

A CVT operates utilizing a procedure of pulleys along with a belt or chain. A single pulley is connected to the engine, and the other is linked to the wheels.

Steel belt style HowStuffWorks The introduction of recent materials would make CVTs much more reputable and economical. Certainly one of A very powerful advances is the look and enhancement of metal belts to connect the pulleys.

Obtaining a reliable transmission expert who is aware his way all around a CVT Along with the similar self esteem as a conventional guide or automated may also be a challenge.

Command Valve: The Handle valve regulates the tension from the transmission fluid from the CVT. This pressure is utilised to regulate the pulley sizes and, consequently, the equipment ratio.

The gear ratios are adjusted with the usage of an ingenious mechanism, which involves a peculiar arrangement with the disk and rollers. The rollers Handle the torque distribution and make infinitely many equipment ratios possible, involving the two extremes.

A repeatedly variable transmission method is often a kind of automated transmission in which an arrangement of pulleys and belts designed it achievable for a push to attain n-range of constant equipment ratios in a range (will depend on the design).

In a standard automated transmission, the gears are practically gears -- interlocking, toothed wheels that aid transmit and modify rotary motion and torque. A mix of planetary gears produces all of the different equipment ratios that the transmission can make, typically 4 ahead gears and a single reverse equipment.

This is not a coincidence. Most CVTs are usually not but effective at dealing with higher-torque purposes with no shattering on their own right into a thousand oily bottlecaps.

It is the sort of shaft and that is held parallel for the input shaft inside of a repeatedly variable transmission, same as input shaft In addition, it has splines more than its cross-section and is particularly mounted on by output pulleys.

Have you at any time pulled out your spark plugs only to uncover them protected in oil? Exploring engine oil on…

If you step to the gas pedal of a car or truck using a consistently variable transmission, you observe the difference promptly. The engine revs up towards the rpms at which it produces quite possibly the most electrical power, after which you can it stays there. Nevertheless the motor vehicle isn't going to respond instantly. Then, a minute afterwards, the transmission kicks in, accelerating the car bit by bit, steadily and without any shifts.

CVT gearboxes are pretty basic of their style and development and are actually in manufacturing for decades, so that they’re rather dependable Therefore. Provided that you stick to a more regular support agenda, a CVT need to be no more problematic than a traditional automated gearbox.